Vehicle Parts Search

CloseProducts By

-

Category

CategoryPower Transmission

- Micro-V Belts Micro-V Belts

- V-Belts V-Belts

- Special Belts Special Belts

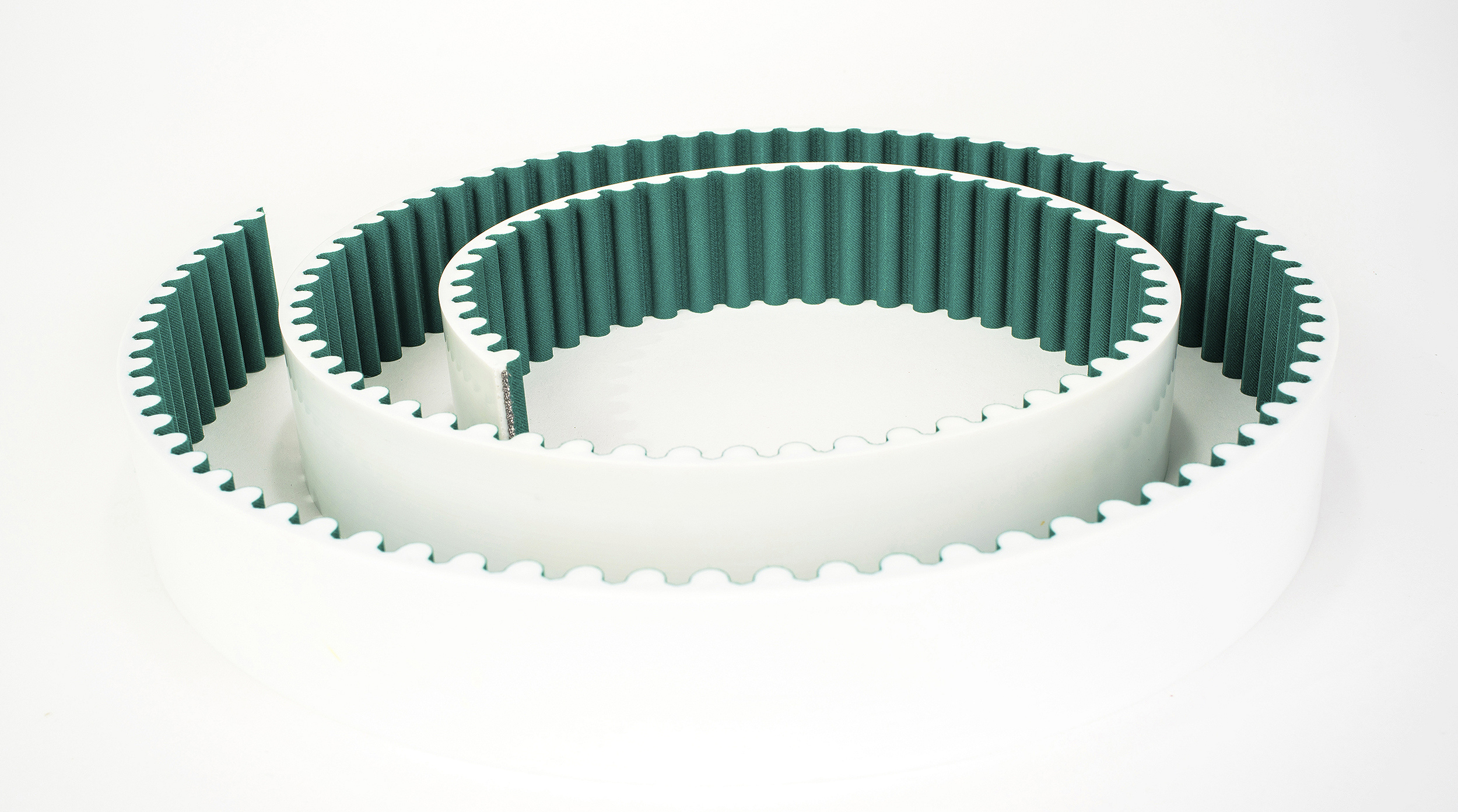

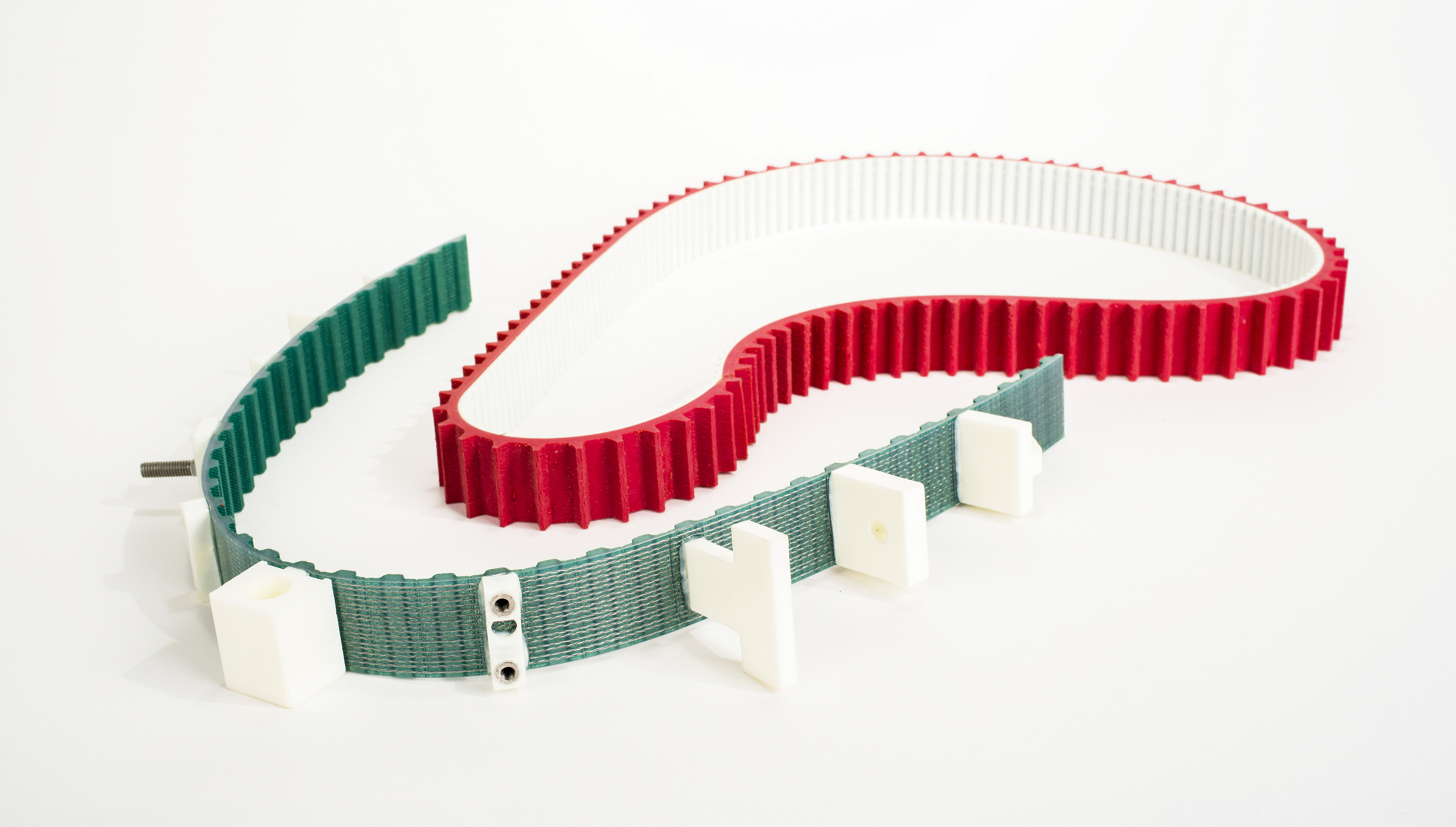

- Synchronous Belts Synchronous Belts

- Automotive Timing Belts Automotive Timing Belts

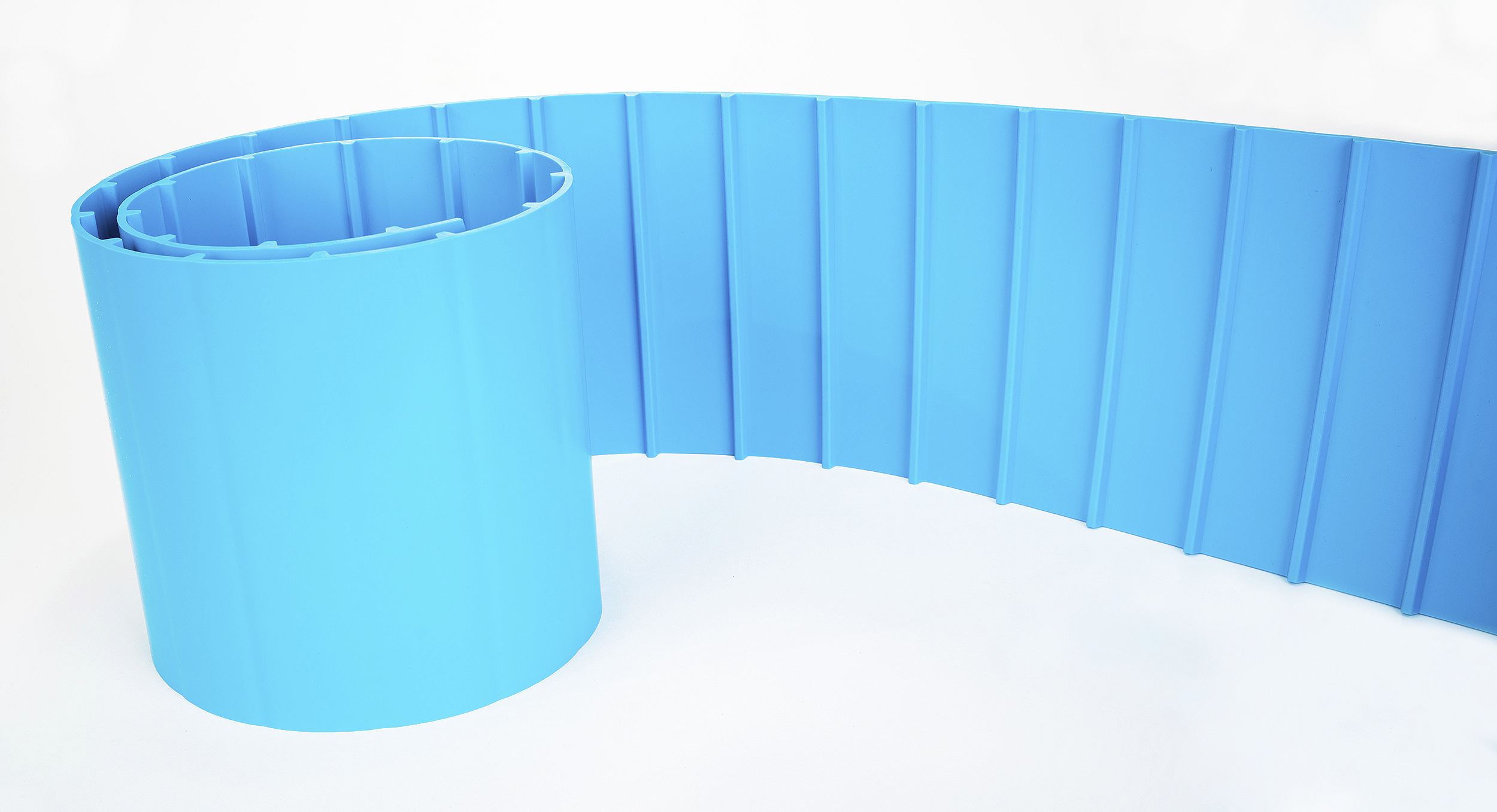

- Gates TPU Polyurethane Belting Gates TPU Polyurethane Belting

- Power Transmission Components Power Transmission Components

- Water Pumps Water Pumps

- Power Transmission Kits Power Transmission Kits

- Power Transmission Tools and Merchandisers Power Transmission Tools and Merchandisers

Fluid Power- Hydraulic Hose and Couplings Hydraulic Hose and Couplings

-

Hydraulic Hose and Couplings

- Air Brake / Compressed Air

- Ball Valves

- Brass Adapters

- Hydraulic Accessories

- Hydraulic Adapters and Valves

- Hydraulic Equipment and Crimpers

- Hydraulic Hose Assemblies

- Live Swivels

- PTFE Hydraulic Hose and Couplings

- Quick Disconnect Couplers

- Spiral Wire Hose and Couplings

- Textile Braid Hose and Couplings

- Thermoplastic Hose and Couplings

- Wire Braid Hose and Couplings

- Hydraulic Tubing and Tube Fittings Hydraulic Tubing and Tube Fittings

- Industrial Hose Industrial Hose

- High Pressure Oilfield Hose High Pressure Oilfield Hose

- Fluid Power Tools and Merchandisers Fluid Power Tools and Merchandisers

- Engine Hose Engine Hose

-

Engine Hose

- Air Conditioning Hose and Couplings

- Coolant Hose

- Coolant Tanks

- Fuel Line Hose

- Heater Control Valves

- Heater Hose

- Power Steering

- Hose Clamps and Couplings

- Cooling Fan Modules

- Turbocharger Oil Line

- SCR

- Vacuum Tubing

- Transmission Oil Cooler Hose

- Air Brake / Compressed Air

- Other Engine Hose

- Air Intake and Defroster Hose

- Air Vent Hose

- Emission Control Hose

- Fuel Fill Hose

- Turbocharger Hose

Other Products- Automotive Accessories Automotive Accessories

- Caps and Thermostats Caps and Thermostats

- Engine Hose (Air Intake/Emissions) Engine Hose (Air Intake/Emissions)

- Service Station and Shop Support Hose Service Station and Shop Support Hose

- Windshield Washer, Wiper and Vacuum Components Windshield Washer, Wiper and Vacuum Components

Product InnovationsProduct Innovations from Gates

You can count on Gates to supply innovative new products that push the boundaries of materials science. We engineer our products to continually exceed expectations and outperform industry standards. We are constantly expanding our product catalog and services to support every facet of our customer's operations.

Vehicle Parts Search

Close- Industries

- Solutions

- Knowledge Center

- About Us